5-Axis CNC Machining

Keller Technology provides complex systems, equipment, and fabrications for a diverse group of industries. To properly support the growth of our customers, we have a program of continual investment in our facilities and equipment.

View our detailed Facilities Listing brochure

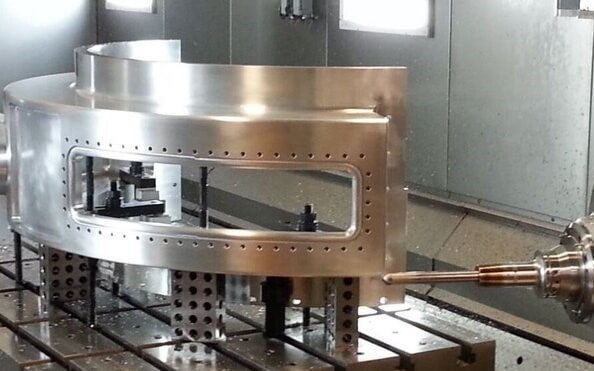

Our state-of-the-art machine shop features a broad range of large envelope machine tools including several 5-axis machining centers. 5-axis CNC machining allows for the spindle and/or work piece to be machined on five sides (top, front, back, left & right sides). Additionally, five axes can be used to simultaneously cut compound angles and other hard to reach surfaces. There are many advantages to this freedom of motion (when compared to 3-axis machining) including:

- Faster removal of material with each tool pass

- Fewer setups to machine complex geometries

- Better surface finishes when machining contours

- Reduction of fixturing tooling

Recent additions to Keller’s lineup of 5-axis machining centers include:

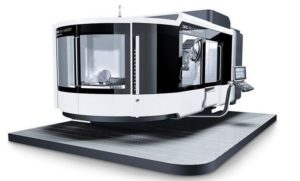

Parpas XS 63 5-Axis Gantry Machining Center

The Parpas is an ideal choice for machining hard-to-reach surfaces and deep cavities. In addition to high speed and the ability to perform heavy-duty machining on hard materials (steel, Inconel, titanium, etc.), the CNC 5-axis mill tool machines highly complex shapes with a single setup. Highlights include:

- Roughing straight milling head (5,000 RPM)

- Universal indexing right angle head (5,000 RPM)

- Universal five-axis high speed milling head (20,000 RPM)

- X-axis travel = 236”

- Y-axis travel = 118”

- Z-axis travel = 59”

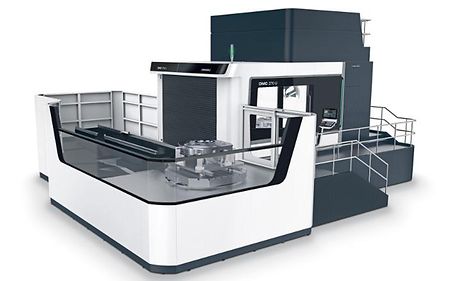

DMG/MORI DMC 210 FD Machining Center

The DMC 210 FD employs a large, stable bridge-type structure for high accuracy and dynamic performance. Productivity is enhanced via 5-sided/5-axis machining with a single setup. FD table with direct drive enabling both machining and turning on one machine. A high-speed pallet changer allows for the next process setup during the 5-axis CNC machining operation. Highlights include:

- powerMaster spindle (12,000 RPM)

- Mill-turn functionality

- 4 wheel tool magazine (243 tools)

- X-axis travel = 82”

- Y-axis travel = 82”

- Z-axis travel = 49”

DMG/MORI DMC 160 U RS6 CNC Machine Center

The DMC 160 U RS6 features a highly stable, actively cooled, and extremely precise duoBlock structure for maximum cutting capacity. Fast and compact 6-pallet rotating pallet changer, and quick tool exchange enhances productivity. Ideal for machining hard-to-cut materials and where surface quality requirements are highest. Highlights include:

- powerMaster spindle (15,000 RPM)

- Mill-turn functionality

- 4 wheel tool magazine (243 tools)

- X-axis travel = 63”

- Y-axis travel = 55”

- Z-axis travel = 43”