Aseptic Process Equipment for Aseptic Environments

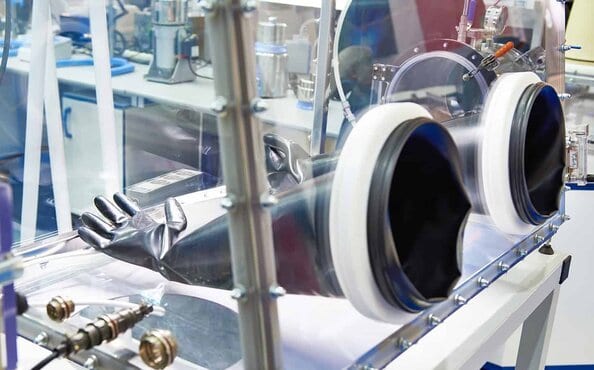

Keller Technology Corporation (KTC) designs and builds aseptic process equipment for the manufacture of sterile products in aseptic environments.

As an aseptic filling machine manufacturer, our engineers are experienced in utilizing industry best practices, working closely with isolator manufacturers to develop custom systems that meet cGMP requirements for aseptic environments.

- KTC provides equipment manufacturing services for combination products, biologics and pharmaceutical industries

- Our custom aseptic filling machines meet cGMP requirements for aseptic environments

- KTC engineers create solutions for custom coating, web handling, fluid handling applications and more

KTC specializes in robotics integration into custom systems for cGMP life sciences applications, including aseptic process equipment, drug discovery, diagnostics, and pharmacy automation machinery. In addition, as a manufacturer of web handling and converting equipment, KTC can provide equipment to handle engineered membranes, thin films, laminated materials, filter and fibrous materials.

Other specialties include:

- Custom coating applications

- Custom primary packaging equipment

- Custom web handling

- Fluid handling

Aseptic environment project profiles

Custom automated system

Biopharmaceuticals, Combination Product

Custom coating system using a customer’s proprietary coating process to coat a biologic API on a medical device.

Custom automated system

Automated Aseptic Dip Coating System Project Profile

Automated aseptic dip coating system—utilizing a Staubli robotic arm—for medical device.

Custom automated system

Aseptic Project Profile 1

An automated system for coating of a drug delivery device with a biologic API.