Custom Machinery

Builds

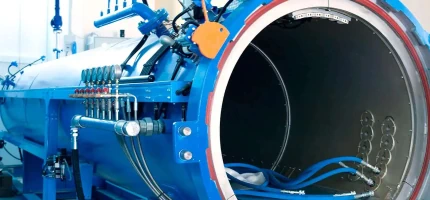

Keller Technology Corporation offers build-to-print services with engineering support for complex custom industrial equipment manufacturing and high-level assemblies for a wide variety of applications and industries. Precision electro-mechanical assembly and integration of highly complex equipment, machinery and systems is our specialty.

With over 100 years of experience in machining, precision fabrication, procurement, assembly, and electromechanical-software integration for complex equipment you can put your trust in Keller to deliver custom industrial equipment on time and on budget.

Explore Our Custom Machinery Manufacturing Facility

Design Update & Global Delivery Case Study

In the competitive healthcare industry, maintaining efficient and up-to-date production systems is critical for ensuring product quality and compliance with regulatory standards. This case study explores a project undertaken to update a complex production system for an international healthcare company.

Our custom machinery capabilities

When you need complex automated, custom industrial equipment manufacturing or precision electromechanical equipment, we know there is no one-size-fits-all solution. As custom equipment builders and automation system manufacturers, we deliver superior quality custom machinery to meet your non-standard requirements.

Turnkey builds. All customer designs are reviewed for completeness, part obsolescence, manufacturability, and cost effectiveness.

Explore advanced manufacturing solutions for applications requiring demanding regulatory compliance and other challenges including critical environments.

We engineer and fabricate custom prototypes, pilot plants and full production lines for new or existing industrial processes.

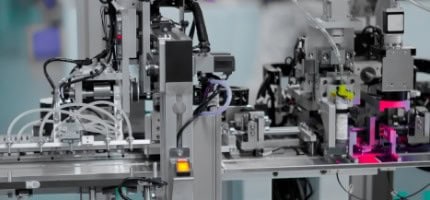

Keller Technology is your resource for multi-step automation machinery for dedicated product manufacturing systems.

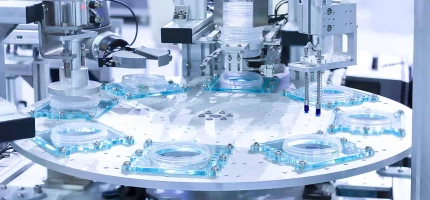

Keller Technology Corporation designs and builds custom machinery for the manufacture of sterile products in aseptic environments.

As custom machine builders, Keller Technology specializes in high precision, complex electromechanical equipment and systems.

We have experience in many types of robotic applications in life sciences, including assembly, specialized coating, material handling and primary packaging.

See how we help customers in the medical industry achieve their quality and productivity goals with custom automation solutions for medical equipment.

Our in-house capabilities are uniquely suited to the production of accelerator and magnet-based medical imaging equipment.

From medical diagnostic and imaging equipment to sophisticated patient handling systems, we manufacture high-level assemblies and turnkey equipment.

KTC is well-versed in machine design and controls engineering, including the ability to upgrade existing equipment and develop second-generation machines and systems.

Keller offers build services for cGMP custom automated equipment for med/pharma products requiring unique dosage, delivery, or packaging .

Value-add services and support

Whether you need a partner to work from existing specifications or you’re looking for design and engineering support, KTC meets you where you are to create custom machinery. We are your go to partner in creating custom machinery that enhances productivity for your needs.

Related resources

Explore our custom machinery manufacturing facility

In our interactive, virtual-environment video, you can explore our custom machinery and contract manufacturing facility in Charlotte, North Carolina, where we create highly complex electromechanical equipment, systems and assemblies. Get 360-degree views of our controlled-environment rooms, where we meet and exceed ISO 7 level requirements to ensure your complete satisfaction.

Certified for quality

For every project that comes through our facilities, KTC is committed to excellence. We have a dedicated quality control system with documented standards and procedures, and we comply with strict quality standards.

Ready to work with us?

Send us your project requirements to receive a custom machinery quote today. We look forward to partnering with you.