Outsourcing vs. In-House Manufacturing: OEM Decision Guide

For OEMs producing high complexity capital equipment, deciding whether to manufacture in-house or outsource to a contract manufacturer is a strategic call with long-term consequences. This decision affects not just timelines and budgets, but also touches quality, compliance, and your ability to scale. At Keller Technology Corporation, we work with OEMs who face this decision every day. […]

World-Class Customer Experience in B2B Manufacturing

10 Essentials for Competitive Advantage Customer experience (CX) has evolved into a critical differentiator in the B2B manufacturing space. Complex sales cycles, high-value accounts, and technical products mean relationships matter—and the companies that deliver world-class service are winning long-term loyalty and higher margins. At Keller Technology Corporation, we’re proud to provide a world-class customer experience […]

Keller Technology Sets Ambitious Goal to Cut Emissions by 21%

Sustainability & Climate Action Advancing Precision Manufacturing with Environmental Responsibility At Keller Technology Corporation, our commitment to precision and innovation goes hand in hand with our responsibility to reduce environmental impact. As a premium U.S.-based contract manufacturer, we recognize that our operations, and those of our customers, must reflect sustainable values and measurable climate goals. […]

Choosing an Industrial Automation Partner for Multi-Site Needs

Are you responsible for high-level industrial automation programs that span locations, perhaps continents, with multi-year budgets? If so, one truth will become abundantly clear: not all partners are built for the long haul. Global manufacturers face a complex challenge: how to standardize automation across multiple sites without sacrificing quality, flexibility, or compliance. Success demands more […]

Sourcing Large-Format 5-Axis Machining

If you have ever tried sourcing large, tight-tolerance machined components, you already know: the larger and more complex the part, the smaller the vendor list. When the part requires 5-axis machining, tight tolerances, and certified welding, the challenge only multiplies. Why is it so hard to find a shop that can manage it all? And […]

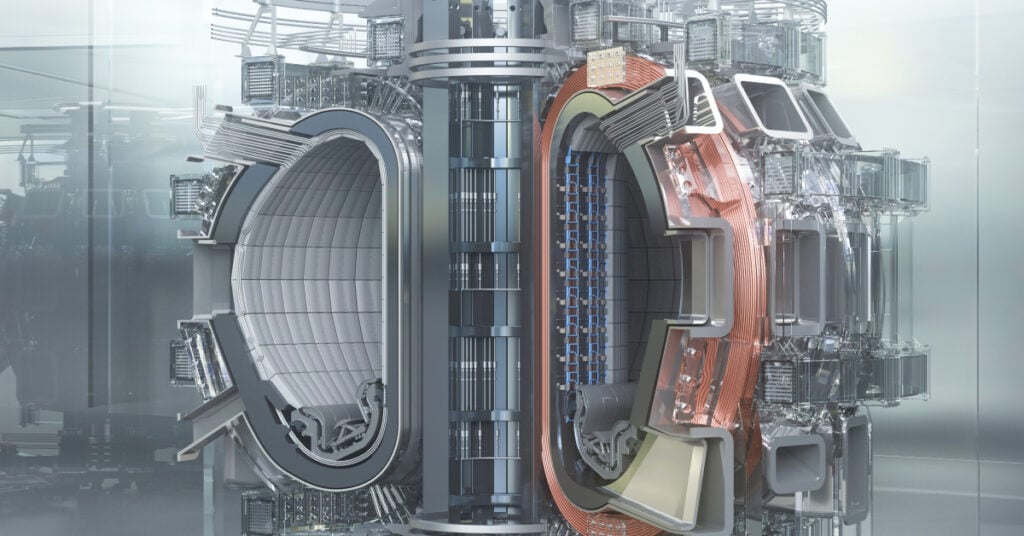

Supporting Fusion Energy Through Machining and Precision Fabrication

Fusion energy, long regarded as the “holy grail” of clean energy, is on the brink of becoming a transformative reality. With global investments surging into the development of several different approaches to achieving fusion, advanced fusion energy machines and reactors, the demand for specialized machining and fabrication expertise has never been greater. At Keller Technology […]