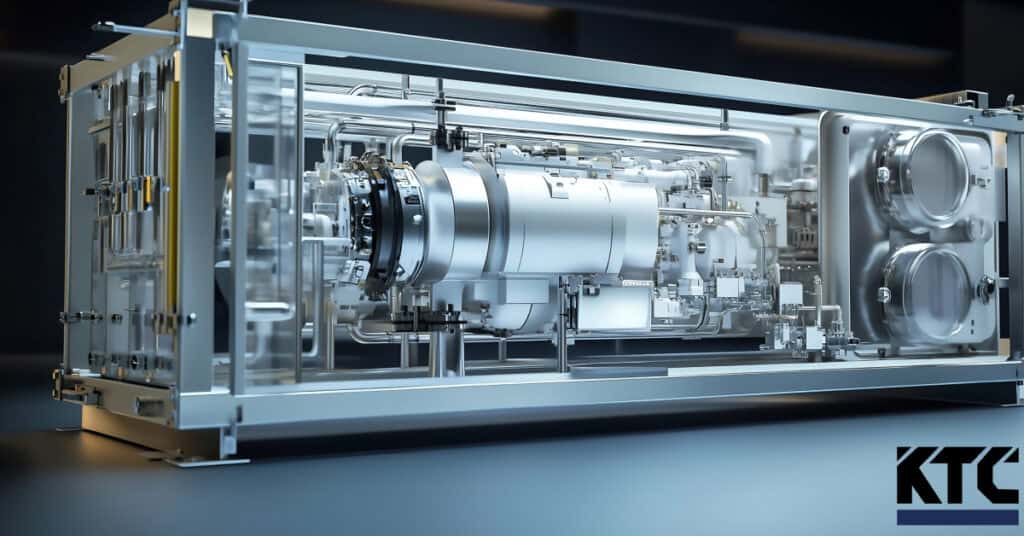

As the global push for clean, reliable energy intensifies, Small Modular Reactors (SMRs) are emerging as a game-changing solution in the nuclear power sector. Designed to be smaller, safer, and more flexible than traditional nuclear reactors, SMRs promise to revolutionize how nuclear power is deployed and scaled. Behind the scenes, precision machining and fabrication are critical to making these innovative reactors a reality. At Keller Technology Corporation, we are proud to leverage our manufacturing expertise in these areas to support this exciting and transformative industry.

SMRs offer a unique combination of benefits. Their modular design allows for factory-based manufacturing, leading to improved quality control, reduced costs, and shorter deployment times. However, manufacturing components for SMRs presents a unique set of challenges, requiring advanced machining and fabrication capabilities to meet strict industry standards and ensure reactor performance and safety.

Challenges in Precision Machining and Fabrication for SMRs

The development and manufacturing of Small Modular Reactors involves overcoming a range of technical challenges. The unique nature of SMRs demands expertise to meet these challenges:

Complex, High-Precision Components

SMRs incorporate intricate parts such as reactor pressure vessels, heat exchangers, and control rod assemblies. These components must meet exceptionally tight tolerances to ensure the safety and efficiency of the reactor. Precision machining ensures every part meets exact specifications.

Handling Advanced Materials

SMR components are often made from specialized materials, including advanced stainless steels, nickel-based alloys, and high-strength composites. These materials are chosen for their ability to withstand high pressures, temperatures, and radiation, but they can be challenging to machine and fabricate. Expert knowledge and state-of-the-art equipment are essential to working with these materials.

Scalable Modular Fabrication

The modular nature of SMRs requires components to be fabricated in a way that ensures seamless assembly at the deployment site. Precision fabrication, including advanced welding techniques and dimensional accuracy, is critical to achieving the modularity and interchangeability that define SMR designs.

Regulatory and Safety Standards

The nuclear industry is governed by some of the strictest safety and quality standards in the world. SMR components must meet rigorous requirements for material traceability, structural integrity, and dimensional accuracy. Advanced machining and fabrication processes are essential to meeting these demanding standards.

Keller Technology Corporation’s Expertise Applied to SMR Manufacturing

At Keller Technology Corporation, we bring decades of experience in high-precision machining and fabrication to support the emerging SMR industry. Our capabilities include:

- Large-Scale Machining: We specialize in manufacturing large, high-precision components to meet exacting tolerances and surface finish requirements.

- Advanced Fabrication: From precision welding to structural assembly, our fabrication expertise ensures that SMR components are built to meet strict safety and quality standards including ASME code.

- Material Expertise: With extensive experience working with high-performance materials, we have the tools and knowledge to machine and fabricate the advanced alloys required for SMR components.

- Comprehensive Solutions: We provide end-to-end support, from prototype development to production-scale manufacturing, helping our customers bring their SMR designs to life efficiently and reliably.

Why Precision Machining and Fabrication Matter for SMRs

The success of the SMR industry relies on the ability to manufacture components that are not only precise but also scalable and reliable. Precision machining ensures that critical parts meet tight tolerances and functional requirements, while precision fabrication guarantees structural integrity and assembly compatibility. Together, these capabilities form the backbone of SMR manufacturing, enabling the industry to meet its ambitious goals for cost, safety, and scalability.

By investing in cutting-edge machining and fabrication technologies, Keller Technology Corporation is positioned to deliver the high-quality components required for SMR projects. Our expertise helps our customers accelerate development timelines and reduce risks while meeting the stringent demands of the nuclear energy sector.

Driving Innovation Through Continuous Investment

At Keller Technology Corporation, we understand that supporting emerging industries like SMRs requires ongoing innovation. That’s why we continuously invest in advanced machine tools, fabrication technologies, and quality assurance processes. Our commitment to staying at the forefront of machining and fabrication ensures that we can meet the evolving needs of the SMR industry and maintain the highest standards of excellence.

Keller Technology – Your Manufacturing Partner

Small Modular Reactors represent a groundbreaking leap forward in the quest for clean, reliable energy. As the SMR industry continues to grow, precision machining and fabrication will play a vital role in making these reactors scalable, efficient, and safe. At Keller Technology Corporation, we are proud to support this emerging industry with our expertise, advanced capabilities, and unwavering commitment to quality.

If your SMR project requires high-precision components or expertly fabricated assemblies, Keller Technology Corporation is your trusted manufacturing partner. Contact us today to learn how our machining and fabrication expertise can help bring your vision for the future of nuclear energy to life.