The Buffalo, NY location of Keller Technology Corporation (KTC) was fortunate enough to maintain a relatively good level of business through the early stages of the pandemic. There was a brief period when customer demand was reduced allowing us to complete some projects we had been trying to implement previously. These improvements have positioned us well for the increased customer demand that we have experienced for the last several quarters. Facility upgrades include:

New Machine Tools – Coming Soon

Two new machine tools have been placed on order: Visionwide FA4127 and DMG/Mori DMC 160. Additional details will be provided on these new additions in our next newsletter.

Larger Clean Room

We have simultaneously moved and increased the size of one of our ISO 7 (class 10,000) clean room. The clean room is now 1350 sq. ft. (30% larger) and occupies a dedicated area that optimizes the process flow within the manufacturing area.

Vacuum Component Cleaning

The spaces previously occupied by our paint shop and supplemental material storage area have been converted and now serve as a zone dedicated to the specialized cleaning requirements for components used in our vacuum systems.

Larger Polishing Department

KTC has doubled the size of our polishing department in order to meet customer demand for projects in the semi-tool space as well as for precision fabrication work for the DOE National Labs. The relocation also serves to further improve process flow throughout our facility.

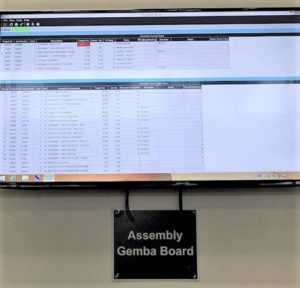

Gemba Walk Leader Boards

As part of our continued commitment to lean methodologies, KTC has added additional visual management tools including leader boards in each manufacturing department. These boards have increased the effectiveness of our regular Gemba Walks.

Machine Monitoring

To leverage our state-of-the-art manufacturing operations, we have introduced Tulip machine monitoring software. This versatile software platform integrates machine, process, and human data to allow for real-time production visibility. KTC is embracing advanced methods and tools like Tulip to take advantage of factory 4.0 efficiencies.

Upgraded Lighting

The health and safety of our customers and employees is paramount, and KTC has been replacing existing light fixtures with higher lumen LCD fixtures throughout our facility. Since much of the work we do requires smooth surface finishes with exacting cosmetic requirements, enhanced lighting also benefits our visual inspection checkpoints on the manufacturing floor.

Keller Technology Corporation continues to make sure our facilities have the best equipment and environment set up to give our customers the best in machine assembly building and manufacturing services. Learn more about our company and contact us for your next project.